додатен прибор

PVC ribbed pipes and screens are made with non-toxic materials and comply with the hygienic requirements of Ministerial Decree n° 174 dated 06/04/2004. Longitudinal grooves prevent sand and gravel from settling near the openings. This allows the rising of water inflow speed, improving the hydraulic features and increasing the flow rate.

Data demonstrate that ribbed screen doubles its permeability compared to a smooth screen of the same dimensions, therefore it is possible to reduce drilling diameter with consequent money saving.

Moreover, the grooves contribute to the stability of the entire column and provide higher resistance to external pressure borne by axial load of carrying tubular section. In horizontal drainages it helps water collecting.

Pic. 1

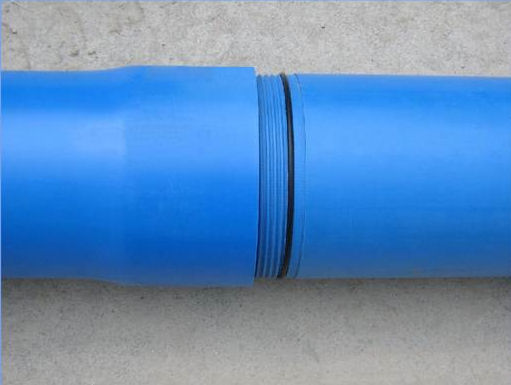

M/F Threaded end with socket.

This kind of connection requires larger overall dimensions compared to the pipe diameter.

Pic. 2

Flush joints. This kind of connection requires the

same overall dimensions as the pipe diameter.

RIBBED PIPES AND SCREENS RANGE

FEATURES |

TESTING METHODS DIN NORM – UNI NORM |

||

Specific gravity |

g / cm3 1,4 |

||

Yield point |

Kg / cm2 338 |

ASTM method |

D 638 |

Load at break |

Kg / cm2 435 |

ASTM method |

D 638 |

Elongation at break |

% 8 |

ASTM method |

D 638 |

Tensile strength |

N / mm2 55 |

DIN 53455 |

|

Kg / cm2 555 |

|

UNI 5819/66 |

|

Modulus of elasticity |

Kg / cm2 26.000 |

|

UNI 7219/72 |

N / mm2 2.600 |

DIN 53457 |

|

|

Shock resistance 20°C |

no breaks |

DIN 53453 |

UNI 6323 |

PVC PIPES RANGE

DIAMETER |

WALL THICKNESS |

SOCKET |

USABLE INSIDE DIAMETER |

WEIGHT |

STANDARD |

||

mm |

inches |

mm |

PN |

mm |

mm |

Kg/mt |

mt |

33,3* |

1” |

3,3 |

PN 10 |

40,0* |

26,7 |

0,48 |

1–3-6 |

42* |

1”1/4 |

3,7 |

PN 10 |

49,0* |

34,6 |

0,68 |

1-3-6 |

48* |

1” 1/2 |

3,3 |

PN 8 |

55,0* |

41,4 |

0,71 |

1-3-6 |

48* |

1” 1/2 |

4,0 |

PN 10 |

55,0* |

40,0 |

0,74 |

1-3-6 |

60 |

2” |

4,2 |

PN 8 |

65,0 |

51,6 |

1,126 |

1-3-6 |

60 |

2” |

4,6 |

PN 10 |

65,8 |

50,8 |

1,22 |

1-3-6 |

75 |

2” 1/2 |

4,5 |

PN 8 |

80,0 |

66,0 |

1,524 |

1-3-6 |

75 |

2” 1/2 |

5,3 |

PN 10 |

82,0 |

64,40 |

1,760 |

1-3-6 |

88,9 |

3” |

5,0 |

PN 8 |

94,0 |

80,0 |

1,930 |

1-3-6 |

88,9 |

3” |

6,5 |

PN 10 |

97,0 |

76,0 |

2,30 |

1-3-6 |

114 |

4” |

5,4 |

PN 8 |

121,0 |

103,2 |

2,80 |

1-3-6 |

114 |

4” |

7,2 |

PN 10 |

124,6 |

99,6 |

3,64 |

1-3-5 |

125 |

4” 1/2 |

6,0 |

PN 10 |

131,0 |

113,0 |

3,50 |

1-3-5 |

125 |

4” 1/2 |

9,3 |

PN 16 |

137,6 |

106,0 |

5,20 |

1-3-5 |

140 |

5” |

5,4 |

PN 8 |

145,0 |

129,2 |

3,60 |

1-3-5 |

140 |

5” |

6,7 |

PN 10 |

148,0 |

129,6 |

4,30 |

1-3-5 |

140 |

5” |

10,4 |

PN 16 |

155,0 |

119,0 |

6,40 |

1-3-5 |

160 |

6” |

6,2 |

PN 8 |

167,0 |

147,6 |

4,60 |

1-3-5 |

160 |

6” |

7,7 |

PN 10 |

170,0 |

144,6 |

5,70 |

1-3-5 |

160 |

6’’ |

11,9 |

PN 16 |

178,0 |

136,2 |

8,42 |

1-3-5 |

165 |

-- |

6,2 |

PN 8 |

172,0 |

152,6 |

4,70 |

1-3-5 |

165 |

-- |

7,7 |

PN 10 |

175,0 |

149,6 |

5,95 |

1-3-5 |

||

165 |

-- |

11,9 |

PN 16 |

177,8 |

141,2 |

8,75 |

1-3-5 |

||

170 |

-- |

7,7 |

PN 10 |

180,0 |

154,6 |

6,06 |

1-3-5 |

||

180 |

6” 1/2 |

7,0 |

PN 8 |

188,0 |

166,0 |

5,84 |

1-3-5 |

||

180 |

6” 1/2 |

8,6 |

PN 10 |

191,2 |

162,8 |

7,10 |

1-3-5 |

||

180 |

6” 1/2 |

13,4 |

PN 16 |

201,0 |

153,2 |

10,69 |

1-3-5 |

||

200 |

7” |

7,7 |

PN 8 |

210,0 |

184,6 |

7,10 |

1-3-5 |

||

200 |

7” |

9,6 |

PN 10 |

214,0 |

180,8 |

8,80 |

1-3-5 |

||

200 |

7’’ |

14,9 |

PN 16 |

224,0 |

170,2 |

13,20 |

1-3-5 |

||

225 |

8” |

8,7 |

PN 8 |

237,0 |

207,6 |

9,00 |

1-3-5 |

||

225 |

8” |

10,8 |

PN 10 |

241,0 |

203,4 |

11,10 |

1-3-5 |

||

225 |

8” |

16,7 |

PN 16 |

252,0 |

192,0 |

16,60 |

1-3-5 |

||

250 |

9” |

9,0 |

PN 8 |

262,0 |

232,0 |

11,30 |

1-3-5 |

||

250 |

9” |

11,9 |

PN 10 |

269,0 |

226,2 |

13,60 |

1-3-5 |

||

250 |

9’’ |

18,0 |

PN 16 |

281,0 |

214,0 |

20,00 |

1-3-5 |

||

280 |

10” |

12,5 |

PN 8 |

300,0 |

255,0 |

16,10 |

1-3-5 |

||

280 |

10” |

16,0 |

PN 10 |

307,0 |

248,0 |

20,20 |

1-3-5 |

||

280 |

10’’ |

21,0 |

PN 16 |

317,0 |

238,0 |

26,30 |

1-3-5 |

||

315 |

---- |

15,0 |

PN 10 |

343,0 |

285,0 |

22,47 |

1-3-5 |

||

330 |

12” |

14,5 |

PN 8 |

353,0 |

301,0 |

22,10 |

1-3-5 |

||

330 |

12” |

19,0 |

PN 10 |

362,0 |

292,0 |

28,50 |

1-3-5 |

||

330 |

12’’ |

25,0 |

PN 16 |

374,0 |

280,0 |

36,87 |

1-3-5 |

||

400 |

14” |

19,0 |

PN 8 |

433,0 |

362,0 |

34,77 |

1-3-5 |

||

400 |

14” |

21,5 |

PN 10 |

438,0 |

357,0 |

39,00 |

1-3-5 |

||

450** |

-- |

18,3 |

PN 8 |

450,0 |

413,0 |

37,00 |

1-3-5,5 |

||

500** |

-- |

20,0 |

PN 8 |

500,0 |

460,0 |

45,50 |

1-3-5,5 |

||

500** |

-- |

29,7 |

PN 10 |

500,0 |

440,6 |

67,50 |

1-3-5,5 |

||

630** |

-- |

24,0 |

PN 8 |

630,0 |

582,0 |

68,25 |

1-3-5,5 |

||

* Only male-male threaded connections with coupling. ( Pic. 3)

** Only flush jointed ( Pic. 4)

* Male-male threaded connections with coupling.

** M/F threaded ends with socket

Pic. 3

Male-male threaded connections with coupling.

Pic. 4

Pipe diam. 450 mm flush jointed.

Available on request:

- Different lengths

- Glue connection pipes

- Rub gaskets (O-ring) for higher tightness of connections